In today’s fast-paced production environments, maintaining consistent quality while optimizing efficiency is essential. intuVision VA Manufacturing offers a robust suite of video analytics tools designed to increase operational efficiency - while ensuring quality standards are met - using the Random Selector feature for enhancing quality control procedures.

intuVision VA Random Selector is an event-agnostic tool and can be used with any configured analytics within the manufacturing workflow. It allows users to designate a fixed percentage of events or items for random selection, offering an unbiased mechanism for inspection sampling. Unlike human-driven selections, which can be unintentionally influenced by habits or physical constraints, the Random Selector ensures a completely impartial sample set for quality control checks, making it more likely to surface a wider variety of potential issues.

In many production scenarios, quality control personnel may unconsciously favor inspecting items that are physically closer or more conveniently located—such as those near the start or end of a conveyor belt, or those within easier reach. While this behavior is natural and typically unintentional, it can result in critical blind spots, resulting defects that occur intermittently or in less accessible areas to go unnoticed. By integrating the Random Selector into the inspection process, manufacturers can counteract this tendency and ensure a more comprehensive and representative sampling of production output.

Quality control standards can vary depending on the shift or individual employees assigned to inspection tasks. Fatigue, experience level, or inconsistent oversight can all impact the thoroughness of inspections. intuVision VA Random Selector brings consistency and accountability to operations eliminating those factors, by maintaining a steady, algorithm-driven selection process. This ensures that each production cycle adheres to the same level of scrutiny, regardless of who is on duty, which is particularly valuable during high-volume production periods or when staffing fluctuates.

Another key advantage of using the Random Selector is the automated reports: for each selected event or item, image snapshots and video clips are recorded and stored, enabling supervisors and quality assurance teams to perform secondary reviews. These visual records can be cross-referenced with employee inspection logs, helping managers confirm that reported defects match observable issues, or to identify discrepancies that may indicate gaps in training or attention.

This built-in audit trail not only enhances the transparency of the quality control process but also reinforces accountability. If patterns emerge where certain employees consistently miss issues identified in random selections, targeted interventions or retraining can be conducted to address the shortfalls.

In addition to supporting quality control within manufacturing operations, the Random Selector can also be configured to validate the performance of intuVision VA’s own video analytics detections. For example, in use cases involving object counting or event detection, a percentage of the generated alerts or counts can be automatically selected and reported with associated visual evidence. These sample detections can then be manually verified to ensure that system outputs are accurate and aligned with expectations.

This dual function—as both a production quality control enhancer and a self-auditing tool—demonstrates the robustness and flexibility of the intuVision VA platform. It ensures confidence not only in the products being inspected but also technology itself.

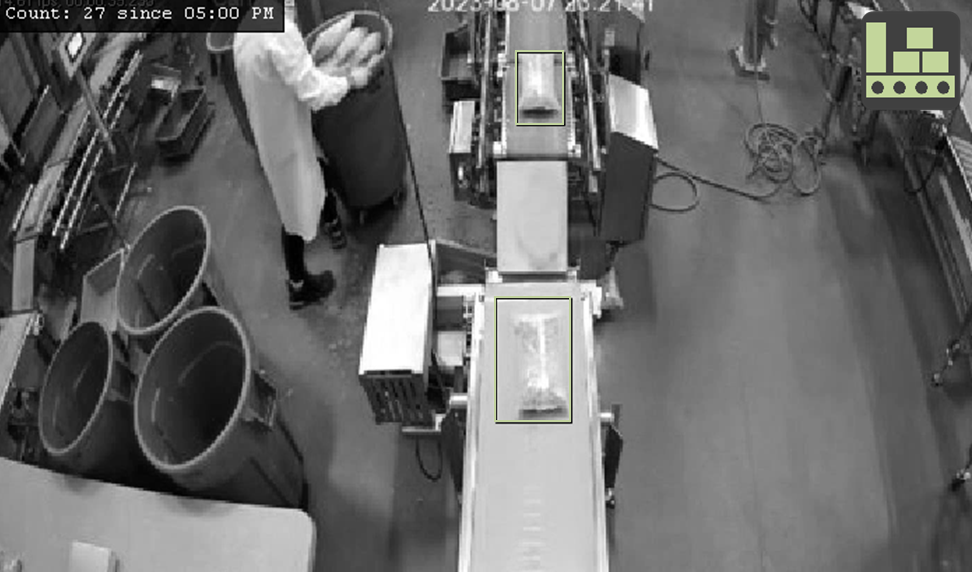

In the following video, you can see an example of intuVision Object Counting and Random Selector in use at a cereal manufacturing facility. Without intuVision VA automation, Quality Control (QC) was done manually, resulting in inconsistent number of samples for each run, and inaccurate QC metrics. intuVision VA Manufacturing automates the item counts and sample collection, for accurate QC metrics without the employee workload. For each production run the items are accurately counted with intuVision VA Object Counting, while the intuVision Random Selector provides truly random samples also reducing.