From helping to maintain uptime and quality assurance on your manufacturing floor, to security, to ensuring safety of employees around dangerous machinery, intuVision VA can be your eyes throughout your manufacturing facility.

Depending on the use-case scenario, intuVision's Review Application and versatile triggers support a wide range of follow-up actions upon event of interest.

intuVision VA's Output Triggers offer such options as generating audio alarms when debris enters the manufacturing process; controlling red/green status lights if dangerous machinery such as forklifts is in walk ways; or sending daily email digests to monitor uptime throughout the factory.

intuVision's rich analytics across application domains makes it uniquely positioned to meet the varied demands of a manufacturing facility. With flexible licensing covering all of our application modules, one can use the same system for security, safety, quality control, even monitoring parking or counting guests!

Many of these analytics events, unlike other solutions, do not require a dedicated camera. Instead any surveillance camera with a clear view of pathways, machinery, or employees can be used. Depending on height and look angle, cameras can be utilized for detecting other events as well, such as after-hours intrusion, smoke and fire detection, etc.

Customer came to us with a requirement to monitor uptime on two of their food processing lines. Due to the unconstrained nature of the items on the tray, as well as their employees' need to reach onto the belt at various times, their existing system was not able to count the trays to a sufficiently high accuracy.

intuVision development team got to work on a custom analytic to meet their needs, a reliable tray tracker that would work regardless of the contents of the trays or other environmental concerns.

Using intuVision automatic email reports, they are able to obtain hourly count emails from both food processing lines, to help ensure optimal uptime. Hourly emails are sent to the line manager, with weekly count comparisons sent to industrial engineering staff. intuVision Reporting is even used for monthly meetings to embed easy to read graphics into presentations.

As this was a custom development, we were able to work with the constraints of the factory, developing the algorithm to work with the views they had. Positioning the camera with a clear unobstructed view of the food processing line, while ensuring the camera remained clean, meant a very specific, close camera view.

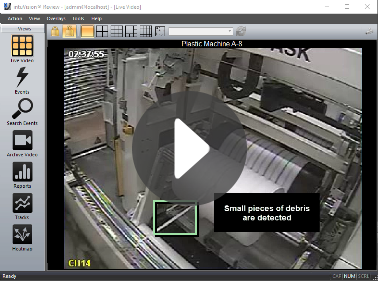

Customer came to us with a requirement to monitor plastic sheeting manufacturing, to ensure debris was not included in the rolls of plastic sheeting. The scenes were dynamic, with machinery moving, the plastic sheeting moving from one machine to another, and unconstrained types of debris.

Using object classification, models were trained to differentiate between the most common types of debris and the machinery, with advanced intuVision algorithms utilized for accurate detection in such a dynamic scene.

Per customer requirement, intuVision triggers were sent to an audio alarm, with employees investigating each instance by watching video in the intuVision Review Application, to ascertain the level of debris.

This solution is ready to deploy with all ONVIF compliant cameras and major VMSs. Cameras should be placed to give a clear line of sight to the manufacturing, without allowing for employees or other machinery to block the view. In this case, small cameras were placed inside the machine to allow the best view.

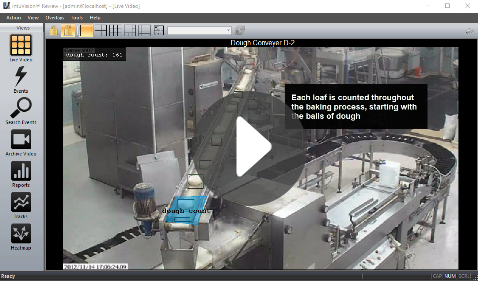

IntellModus analyzed the factory operations and established the solution requirements. Throughout the brad factory they installed over 90 cameras, three cameras per production line to monitor the conveyor belts for the dough balls, baked loaves and packaged bread.

The system feeds live video from the cameras into intuVision Video Analytics to be analyzed in real-time to:

The production cycle item counts and losses at each step are detailed for every run, the reports are automatically e-mailed to responsible operations personnel for each shift. Being able to see these reports immediately helps operations managers to address the production problems and losses in a timely manner.

Using intuVision video analytics IntellModus delivered an automated loss-prevention solution for the bread factory. intuVision VA provides accurate counts of product at each stage of manufacturing process and provides custom reports summarizing production cycle’s throughput.

Monitoring and automatically detecting sources of loss during production significantly increased the operational efficiency of the factory.

IntellModus worked with intuVision to determine the optimal positions for the cameras over the conveyor belts to reach accurate counts using video analytics. As intuVision VA is ONVIF compliant, IntellModus was able to use low cost cameras, to deliver an affordable system to their customer.

Our integrator came to us with a customer requirement of ensuring employee safety in dangerous forklift paths. The area featured a blind corner around which employees would not know if a forklift or other machinery was present, and vice-versa. This led to dangerous situations where employees would be put at risk.

Using flexible intuVision compound events and classification, the customer was able to reliably detect and alarm when a forklift was in the pedestrian walk way, signaling red/green status lights to indicate if it was safe to travel. A similar system was set up for the forklifts, to signal a warning audio alarm if a pedestrian disobeyed the status lights and unsafely entered the area.

The alternative to this system would have been a highly costly modification to their manufacturing floor. intuVision VA was able to use their existing cameras, further keeping costs down.

Ceiling mounted cameras, providing clear and unobstructed views of both forklifts and people were perfect for this application. intuVision VA was able to use existing security cameras, further keeping costs down.